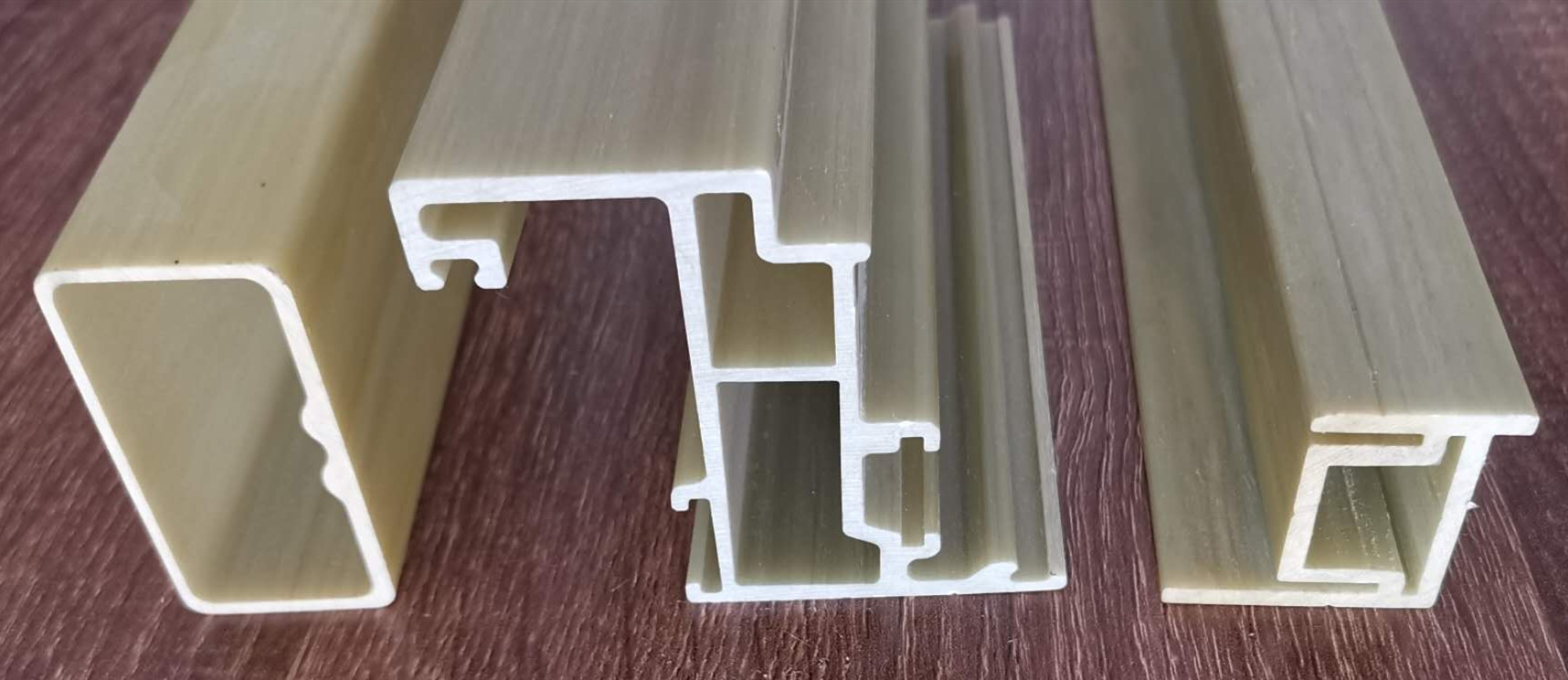

Nowadays, The FRP products are widely used in our industrial and daily life. FRP profiles are popular thanks to their excellent properties such as colorful surface, good looking, high strength, light weight ,insulation ,anti fire and chemical resistant.

When profiles have the same section and are required at a large quantity, pultrusion technology is one of the good choices.The fiberglass profile pultrusion production line is composed of the fiberglass moving shelf, pultrusion die with preform, heating device,pultrusion machine, electrical control switch etc.

The raw material for fiberglass profile products includes fiberglass, resin and hardness agent and other accelerators.

The process of the fiberglass profile manufacture: Firstly, choose the pultrusion die of suitable diameter and put it on the shelf; secondly, calculate the fiberglass roving quantity and guide the fiberglass roving to go through the pultrusion die and into the pultrusion equipment, and then start the heating parts to heat the die to proper temperatures at its entry and exit respectively; finally; pour the mixed resin into the device and start the vacuum system. This is the general process of the fiberglass profile pultrusion technology.